This series of injection molding machines adopts a composite mold insulation device, a special hot kerosene internal circulation barrel, and is equipped with a professionally designed thermosetting plastic screw assembly, which is suitable for processing various thermosetting plastics.

XY series thermosetting injection molding machine

This series of injection molding machines adopts a composite mold insulation device, a special hot kerosene internal circulation barrel, and is equipped with a professionally designed thermosetting plastic screw assembly, which is suitable for processing various thermosetting plastics.

Mold clamping part

It has an obliquely arranged five-point toggle mechanism, computer parameter optimization design, and the template is designed through finite element analysis. It adopts a box-type bracket template conjoined structure and a mechanically adjustable movable template support to ensure the rigidity and service life of the mold closing parts.

Hydraulic part

It adopts imported famous brand hydraulic components, differential high-speed mold clamping device, and multi-level injection control. The system adopts pressure-flow proportional control and reserves a standard core-pulling device. The mainframe is equipped with a logic cartridge valve system to ensure that the machine operates at its best.

injection part

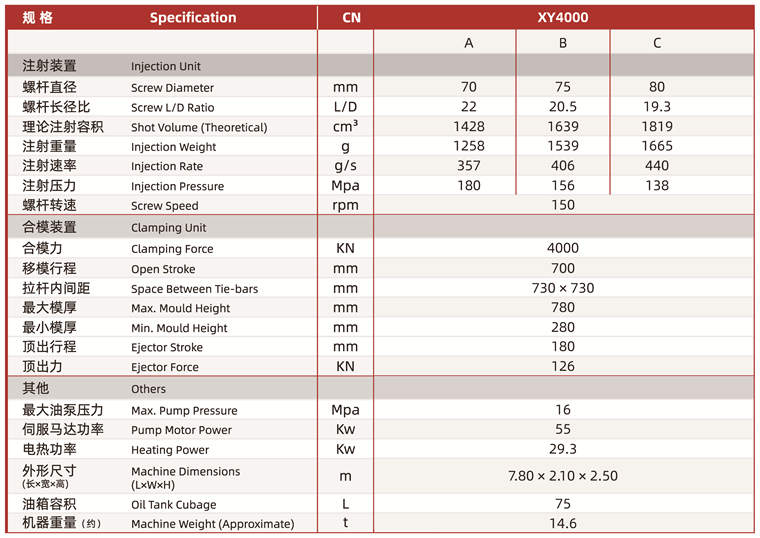

Double guide pillar support, double cylinder balanced injection, stepless high-torque hydraulic motor directly drives the screw melting device, force-sealed seating device, high-quality nitrided alloy steel screw and barrel, surface bimetal treatment to extend life, available for A , B, and C diameter screws, combined with a variety of special injection devices, ensure the injection molding of various materials.

electrical components

Adopting imported special computers for plastic machines, CPU division of labor control and processing, multiple sets of mold molding data storage functions, multi-point PID material temperature control, injection, pre-molding, and mold opening and closing movements are controlled by high-precision electronic rulers to improve the response speed and stability of the control system. sex.

XY series servo energy-saving injection molding machine

Servo energy-saving injection molding machine, the output power changes with the load, and there is no waste of excess energy. The cooling servo motor does not work and the power consumption is 0. Compared with traditional injection molding machines, servo energy-saving injection molding machines can save 20%-80%, bringing you real savings and significant economic benefits.

High response characteristics of servo motors

Due to the use of high-response servo motors and internal gear pump power systems, it only takes 0.05s for the injection molding machine to reach maximum output. Compared with traditional injection molding machines, the response speed is significantly faster, effectively shortening the cycle and improving production efficiency.

Injection repeatability comparison

The precision characteristics of the servo motor are superimposed on the precision characteristics of the internal gear pump, and a closed loop is formed through a highly sensitive pressure feedback device. The injection repeatability can reach 3%o. Compared with traditional hydraulic presses, it shows stronger injection stability and molded products. The pass rate has been greatly improved.

Have any questions? We are always open to talk about our Products, business, news, creative opportunities, and how we can help you.